Hard water can be a hidden culprit behind many household problems—from soap scum and limescale buildup to shortened lifespans of appliances. Installing a water softener is a practical solution to these issues, and while hiring a professional is always an option, many homeowners choose to take the DIY route. If you’re ready to improve your water quality and reduce plumbing wear and tear, this comprehensive plumbing guide will walk you through the key steps of installing a water softener.

Understanding How a Water Softener Works

Before getting your hands dirty, it’s essential to understand what a water softener does. These systems work by replacing minerals like calcium and magnesium—which cause hardness—with sodium or potassium ions. This process, known as ion exchange, helps prevent mineral buildup in pipes and appliances. Most water softeners come with a mineral tank, a brine tank, and a control valve that manages the entire process. Familiarizing yourself with these components will make the installation smoother.

Before getting your hands dirty, it’s essential to understand what a water softener does. These systems work by replacing minerals like calcium and magnesium—which cause hardness—with sodium or potassium ions. This process, known as ion exchange, helps prevent mineral buildup in pipes and appliances. Most water softeners come with a mineral tank, a brine tank, and a control valve that manages the entire process. Familiarizing yourself with these components will make the installation smoother.

Choosing the Right Location for Installation

Selecting the best place to install your water softener is crucial. It should be close to where the main water line enters your home so that all the water gets treated before it’s distributed to the rest of your plumbing. Common locations include basements, utility rooms, or garages. Make sure the area has a nearby electrical outlet for the system’s control valve and access to a drain for flushing the brine solution. The location should also be dry, level, and free from freezing temperatures.

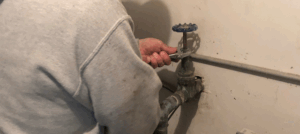

Turning Off the Water Supply and Draining the System

Safety is a top priority when working with plumbing. Start by shutting off the main water supply to your house. This prevents water from flooding your workspace when you cut into the plumbing lines. Once the water is turned off, open the lowest faucet in your home to drain the remaining water from the pipes. You may also want to relieve pressure by opening other faucets around the house. This step helps avoid unexpected leaks during installation.

Cutting Into the Main Water Line

After ensuring the pipes are empty, it’s time to cut into the main water line. Use a pipe cutter to make a clean, straight cut where the softener will be installed. This typically occurs just after the water meter and before the water heater, so only cold water flows through the softener. It’s important to measure carefully and cut accurately to avoid misalignment when connecting the softener. Have a bucket or towel handy to catch any residual water in the line.

Installing Bypass Valves and Connectors

Most modern water softeners come with a bypass valve that allows water to bypass the unit when necessary—such as during maintenance. Attach the bypass valve according to the manufacturer’s instructions. Then, connect the inlet and outlet ports of the water softener to your cut plumbing lines. Ensure the inlet is connected to the supply line and the outlet goes to the house’s plumbing system. Use flexible copper or PEX tubing for easier adjustments, and make sure to secure all connections with compression fittings or soldering, depending on the type of pipe used.

Connecting the Drain Hose and Overflow Line

The system needs to discharge wastewater from the regeneration cycle, so it’s critical to properly connect the drain line. Attach the drain hose to the water softener’s control valve and run it to a nearby drain, utility sink, or standpipe. Secure the hose to prevent backflow or dislodging. Additionally, connect an overflow line to the brine tank and direct it toward a floor drain or another safe outlet. Always follow local plumbing codes for drainage and backflow prevention.

Powering Up and Programming the System

Once all plumbing connections are in place, plug in the unit to a nearby GFCI electrical outlet. Powering up the control panel allows you to configure the system. Most water softeners let you program settings such as the current time, hardness level of your water, and regeneration cycle frequency. Refer to the user manual for exact instructions on entering this data. Proper configuration ensures the unit performs efficiently and effectively.

Adding Salt to the Brine Tank

The final preparation step is adding the correct type of salt to the brine tank. Use water softener salt pellets, which are designed to dissolve slowly and efficiently during regeneration. Pour in the recommended amount and fill the tank with water according to the manufacturer’s guidelines. Some systems may require you to initiate a manual regeneration cycle for the first use, helping to flush out air pockets and prepare the resin bed for operation.

Checking for Leaks and Testing the Water

With the system powered and filled, it’s time to restore water flow. Slowly open the main water valve to allow water to enter the softener. Carefully inspect all fittings and connections for leaks. If everything appears watertight, run a few faucets in the house to flush out air from the pipes. After a few hours of operation, test your water using a hardness test strip. If installed correctly, the test should show significantly reduced hardness levels.

With the system powered and filled, it’s time to restore water flow. Slowly open the main water valve to allow water to enter the softener. Carefully inspect all fittings and connections for leaks. If everything appears watertight, run a few faucets in the house to flush out air from the pipes. After a few hours of operation, test your water using a hardness test strip. If installed correctly, the test should show significantly reduced hardness levels.

Troubleshooting Common Installation Issues

Sometimes even a careful installation can encounter problems. If you notice low water pressure, it might be due to a kinked hose or incorrect bypass setting. Leaks can result from loose fittings or improperly sealed joints. If the water isn’t softening, double-check the inlet and outlet connections—they might be reversed. Reviewing the manufacturer’s troubleshooting guide and user manual can help diagnose and resolve many common issues quickly.